charpy impact testing for a36 steel 10mm|charpy impact energy : member club The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

You found our list of the best rapid fire questions. Rapid fire questions are quick-response prompts players ask each other to find out the first answer that comes to mind. For example, “what do you like on toast?” and “where is your dream destination?” Ver mais

{plog:ftitle_list}

12 de nov. de 2023 · © 2024 BBC. The BBC is not responsible for the content of external sites. Read about our approach to external linking.

If your material is over 4 to 12 inches in thickness, A36 plate is available with Charpy 15 ft.-lb. longitudinal impact toughness at a temperature of -40 degrees Fahrenheit ( . I found a temperature / impact performance graph of the A-36 material this morning. While it did not list the thickness, it generally showed that it would be in the neighborhood of 10 ft.lbs at -20F. I'd be interested in 1/2" thick . A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity .

A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity allows converting energy values to fracture.

charpy impact test pdf

In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy V-notch test is an engineering method that is frequently used to measure the toughness of a material, where the toughness represents the amount of energy a material can .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

A standard Charpy test is performed by machining a 10mm x 10mm x 55mm test piece with a notch cut at the intended fracture point. The test sample is then brought down to .The Charpy LCVN model is statistically robust for ASTM A36, A516 Gr70 and A572 Gr50. The model agrees with metallurgical theory. C and Mo show a strong influence on Charpy impact . Yes, to your second question. The cold rolled will have slightly lower notch toughness, provided both steel plates were provided in the same heat treatment condition (hot rolled, air cooled). The problem with A36 with regards .

A capsule containing Charpy V-notch (CVN) and mini-tensile specimens was irradiated at ~30°C (~ 85°F) in the cavity of a commercial nuclear power plant to a fluence of 1 x 10 16 neutrons/cm 2 (>1 MeV). The capsule included six CVN impact specimens of archival High Flux Isotope Reactor A212 grade B ferritic steel and five CVN impact specimens of a well .Although this CVN impact test data does not represent the real fracture toughness data, this data can be used as a series of points to estimate toughness in an evaluation . Fracture Toughness and Charpy CVN Data for A36 Steel with Wet Welding Soldagem & .Explore the Charpy V-notch impact test, a standard measure of a material's impact energy during fracture. . Charpy Impact Steel Testing: Part One. . The standard Charpy-V specimen, illustrated in Figure 1. is 55 mm long, 10mm square and has a 2 mm deep notch with a tip radius of 0.25 mm machined on one face. .

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.1730 : 1989 Dimensions for steel plates sheets, strips and flats for general engineering purposes (second revision) IS No. Title 1732 : 1989 Dimensions for round and square steel bars for structural and general engineering purposes (second revision) 1757 : 1988 Me thod for Charpy impact test (V-notch) for metallic material (second revision)

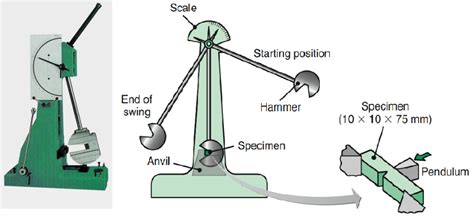

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.lbf) 27 (20) Structural shapes, alternate .

E-mails: [email protected] (GTM), [email protected] (SICC), [email protected] (JCV), [email protected] (DAH), [email protected] (ETS), [email protected] (AQB) Abstract: This study presents KIC data obtained from KIC-CVN correlations from Charpy CVN values. For this study, T-welded connections were .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . The standard Charpy-V notch specimen is 55mm long, 10mm square and has a 2mm deep notch with a tip radius of 0.25mm machined on one face. In .

steel plate would pass a Charpy impact test has been developed. This was done to prevent testing material that would not pass the required Charpy test, without . There were more A36 plates than A516-70 or A572-50. Figure 4 shows the average Charpy impact . energy for each grade, with the average test temper-Charpy V-Notch Impact Testing ENGR45 – Materials Science Laboratory Chad Philip Johnson Submitted: May 15th 2013. . A36 Steel Charpy V-notch measured values.-80 -60 -40 -20 0 20 40 60 80 100 0 50 100 150 200 250 A36 Steel Charpy V-notch Energy vs. Temperature Temperature (°C) E n e r g y (f t-l b)

Since fracture or failure behavior depends on temperature, Charpy impact tests are often performed in the entire operating temperature range. This shows at what temperature and to what extent the material becomes brittle (tough-to-brittle transition).. The example diagram shows that the decrease in strength of mild steel at -40 °C is 25 % in relation to the strength at 0 °C.

A36 plate is available with Charpy 15 ft.-lb. longitudinal impact toughness at a temperature slightly greater than -50.8 (-46 C) degrees Fahrenheit in plates up to 4" inclusive in thickness. If your material is over 4 to 12 inches in thickness, A36 plate is available with Charpy 15 ft.-lb. longitudinal impact toughness at a temperature of -40 .Charpy Test The Charpy test is a good way to measure material toughness. It is useful for materials that exceed the 10.mm (0.394.inches) Charpy height. Specimens can also be made in ¾, and ½ sizes so in theory a 0.20 inch thick specimen can be produced. The Charpy specimen is relatively easy to make and test. The Charpy impact test (CVN) is still the most widely used test for evaluating the absorbed energy and transition temperature of line-pipe steels because of its simple testing method and fewer .); Charpy impact energy (CVN); Wet welding; A36 Steel; Porosity. 1. Introduction It´s widely recognized that Charpy CVN impact energy values can be converted to K IC using K IC-CVN correlations [1-7]. In this context, plane-strain fracture toughness (K IC) is an important material property in the prediction and prevention of fracture, and for

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of . 1.1 This specification covers the procedure for Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as-rolled, control-rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide .

charpy impact energy vs temperature

Scope1.1 This specification covers carbon steel shapes, plates, and bars of structural quality for use in . A0036_A0036M-01|en-US Standard Specification for Carbon Structural Steel Standard A36/A36M Standard Specification for Carbon Structural Steel> new BOS Vol. 01.04 . such as fine austenitic grain size and Charpy V-notch impact testing. Material Testing A36 & A572 Steel Plate. When used in colder environments, structural project engineers may request a Charpy impact test be performed on A572 and A36 materials. Charpy tests measure the ability of a material to withstand great forces within specific temperature ranges, which is crucial to ensure structural materials do not break or fail in harsh .results from the Charpy impact test of the Titanic hull steel for the longitudinal and transverse rolling directions with a modern ASTM A36 mild steel [7]. Unfortunately for the purposes of a direct correlation of properties and microstructure, the comparison of mechanical behavior was• Charpy V-notch test specimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steel • Charpy testing machine with 800-mm long pendulum arm and 22.6-kg impact head . Schematic of Charpy Impact Testing and Izod and Charpy V-notch specimens Figure 2 Charpy V-notch specimen used in this laboratory showing dimensions

The steel plates can be used as bearing plates for bridges and other structures. The ASTM A36 steel shall be killed and generally it is a typical carbon steel. When necessary, a minimum of 0.20% copper shall be added to improve its corrosion resistance in damp or humid conditions. . Charpy V-Notch impact test can be performed upon customer .

hach titralab kf1000 series volumetric karl fischer titrator 3 980 store

charpy impact energy calculation

Resultado da Applegate teve papéis principais em vários filmes, incluindo Don't Tell Mom the Babysitter's Dead (1991), The Big Hit (1998), The Sweetest Thing .

charpy impact testing for a36 steel 10mm|charpy impact energy